Tempest Mk. V

(Standard boxing)

The Hawker Tempest was arguably the best fighter aircraft used by the Royal Air Force in the Second World War. The Tempest was an improved derivative of the Hawker Typhoon, originally known as the Typhoon II, which was intended to overcome the Typhoon's problems of performance at higher altitudes by replacing the wing with a thinner laminar flow wing. After all the modifications the resulting aircraft greatly differed from the Typhoon, the powers that be chose to rename the aircraft, Tempest. The Tempest emerged as one of the most powerful fighters of the WWII and was the fastest propeller-driven aircraft of the war at low altitude.

Early 1943 saw a production line for the Tempest V established at Hawker's Langley facility. Production was initially slow, with blame being attributed to problems encountered with the rear spar.

In June 1943, the first production Tempest V, JN729, rolled off the production line and the maiden flight was made by test pilot Bill Humble. Several of the early production aircraft was used for experimental purposes; a number took part in extensive service trials at RAF (later RAE) Boscombe Down. These including the fitting of external stores, including 500 lb (227 kg) and 1,000 lb (454 kg) bombs and 3 in (76.2 mm) RP-3 rockets, very few Tempest Vs used these stores operationally during the War. In early April 1944, the Tempest V attained general clearance.

During the production of the first batch of 100 Tempest V "Series Is", which all carried the serial number prefix JNxxx, had several improvements were progressively introduced and were used on all following Tempest V "Series 2s", with carried the serial number prefixes EJ, NV and SN. The rear fuselage joint originally had twenty external reinforcing "fishplates", similar to those fitted to the Typhoon. However, it was not too long before the rear fuselage was strengthened and the fishplates were no longer needed. This meant that the rear fuselage became detachable. The first series of Tempest Vs had a built-up rear spar bulkhead assembly situated just behind the cockpit, which was adapted from the Typhoon. The small blisters on the upper rear wing root fairing covered the securing bolts. This was later changed to a lightweight assembly which connected to new spar booms; the upper wing root blisters were then replaced by small "teardrop" fairings under the wings.

The first 100 Tempest Vs were fitted with 20 mm Hispano Mk.IIs with had long barrels which projected ahead of the wing leading edges and were covered by short fairings. Later Tempest Vs switched to the short-barrelled Hispano Mk.Vs, where the muzzle was flush with the leading edges. The early Tempest Vs used Typhoon-style 34" x 11" five-spoke wheels, but most had smaller 30" x 9 " four-spoke wheels. The new spar of the Tempest V allowed for up to 2,000 lbs of external stores to be carried underneath the wings.

As in all mass-produced aircraft, there may well have been some overlap of these features as new components became available. In mid to late 1944 other features were introduced to both the Typhoon and Tempest: A Rebecca transponder unit was fitted, with the associated aerial under the portside centre section.

In spite of the Tempest V being the RAF's best low to medium-altitude fighter, it was not equipped with the new Mk IIC gyroscopic gunsight, as fitted in RAF Spitfires and Mustangs and one which considerably improved the chances of shooting down enemy aircraft.

Two Tempest Vs, were fitted with Napier Sabre Vs and experimented with several different Napier-made annular radiators, which resembled the ones used on was Tempest IIs. This configuration proved to generate less drag than the standard "chin" radiator, which meant an improvement in the maximum speed of some 11 to 14 mph. One of the test Tempests were later fitted with a ducted spinner, similar to that fitted to the Fw 190 V1. Another experimental Tempest V was fitted with a Vickers 47 mm "P" anti-tank gun, this development was never deployed in this layout.

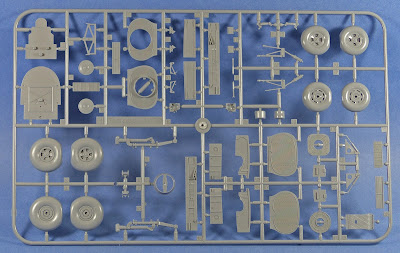

Special Hobby's released this standard boxing of their Tempest Mk. V following on from their Hi-Tech boxing. The Hi-Tech boxing contained lots of resin and photo etch, whilst this boxing omitted the resin and PE, which should appeal to those modellers who do not like working with detailing parts and just want a standard kit, or to those modellers that want to add their own versions of after market parts which are begining to appear on the market this will allow the modeller to detail the kit to their own specification. This also means that the kit costs less for those modellers on a tighter budget The basic kit is the same as the hi-tech boxing with same detailed parts.

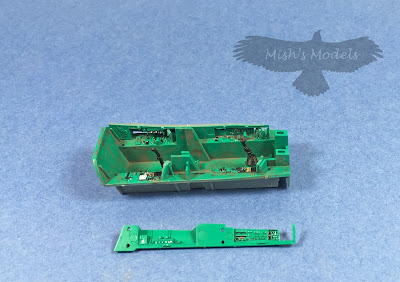

The build follows the tried and tested formula of constructing the cockpit first followed by the fuselage and wings. The cockpit as with the rest of the kit is well detailed. However, I would be very tempted to add some aftermarket seatbelts whether they be photo etch or fabric. The latter in my opinion look and lay more natural.

The level of drtailing can be seen from the following photos:

There are four markings options in this boxing, all share the same Ocean Grey/Dark Green camo

Schemes in the box are:

- NV969 / SA-A No. 486 [NZ] Sqn RAF, Fasberg, Germany April 1945. Personal machine of Sqd Ldr Warren "smokey" Schrader,

- JN862 / JF-z, No.3 Sqn RAF, RAF Station Newchurch August 1944. Full invasion striped carried.

- EJ705 / W2-X No.80 Sqn RAF. Vokel, Netherlands Jan 1945, (only under fuselage stripes carried)

- SN165 / ZD-V No. 222 Sqn RAF, Malden, Netherlands April 1945

The supplied decals are on three sheets. The decals are printed by Eduard for Special Hobb. The register and colour are good as is the sharpness of the printing.

Conclusion

My thanks to Special Hobby who supplied this wonderful review kit.

Conclusion

My thanks to Special Hobby who supplied this wonderful review kit.